Thermal coatings

Optimise quality &

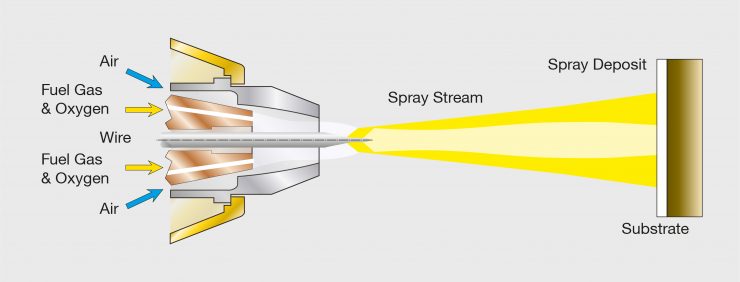

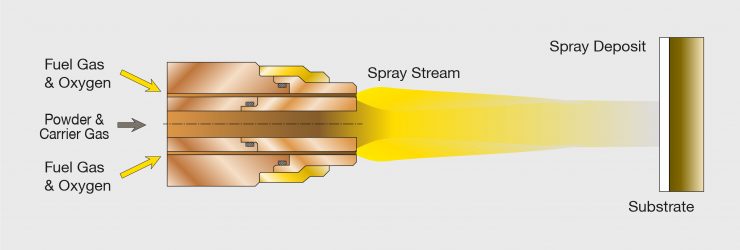

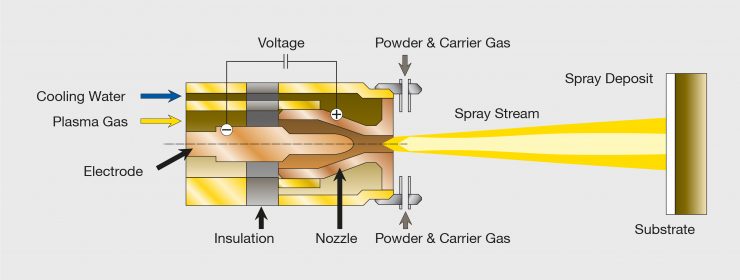

In thermal coatings, various spraying methods are available that differ based on the type of spraying filler material, the manufacturing or the energy carrier. The individual thermal spraying methods do not compete in their application, rather they complement each other with their specific process characteristics and are adapted to the demands of our customers.

Report about Horn in Chemiereport

The sculpture “Sparefroh!“ (Happy Saver) – as an original representation of the large savings potential through correct coatings – adorned the cover of “GTS Strahl”. The Austrian professional journal “Chemiereport” published an extensive report on the topic of “Thermal coatings” about the company Horn and our special expertise. You can catch up now …

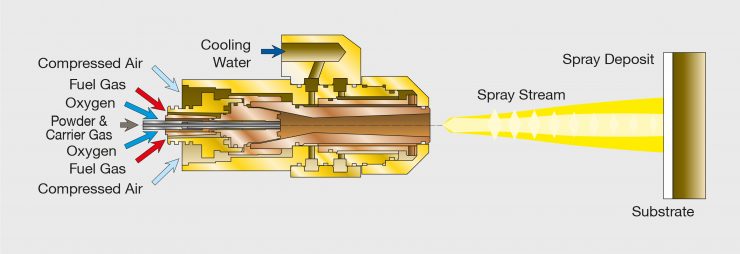

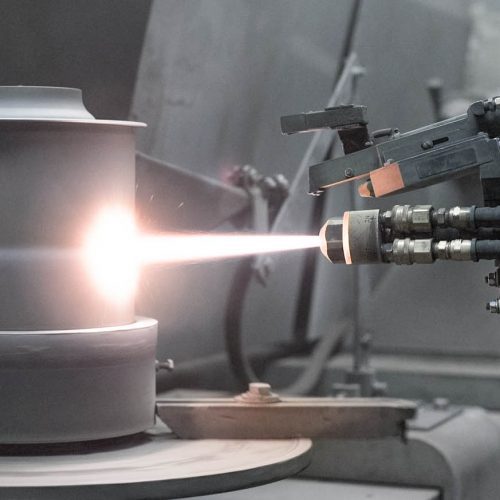

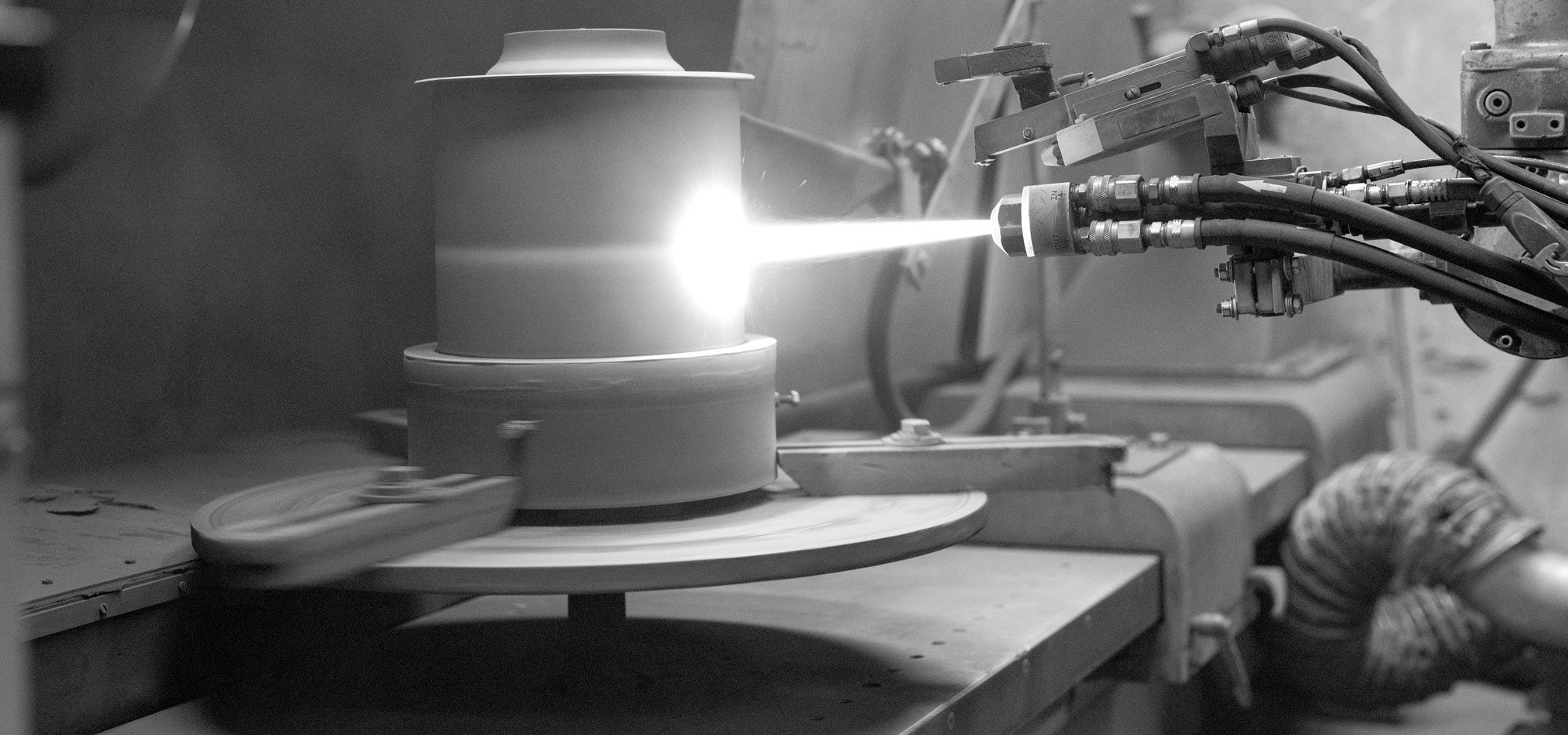

High-speed flame spraying

A fuel is burnt in a combustion chamber. The high pressure that arises during this facilitates a gas jet that applies the fused particles to the coating material on the workpiece. Layers develop that have excellent adhesive properties.

Flame temperature: 2800 ° C 5070 ° F

Particle speed: 400 to 800 m/s 1312 to 2600 fs/s