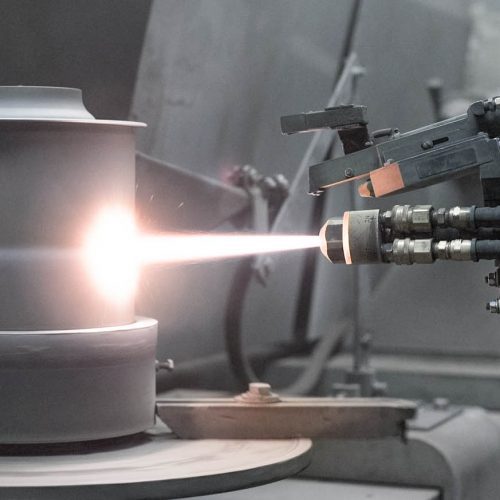

CNC cutting

Precise, reliable and with high quality. That is ensured by extensive investments in pioneering machine technologies. Cutting and processing with the expertise of a tank constructor and mechanical engineer.

Cutting technologies:

Water jet cutting 2D and 3D

- No thermal impact (warpage, surface hardening)

- High precision (saves during mechanical processing or complete omission of the mechanical processing)

- Low cutting gap of 0.8-1 mm even with large material thicknesses

- Material thicknesses of 0.05 mm-120 mm can be machined

- Special materials:

- Composite materials GFRP, carbon (CFRP), profiles…

- Hard faced and coated components

- Halving or trimming turned parts and tubes

- Assembly rework – manufacture of cut-outs acc. to drawings (tubes, hemiellipsoidals, welding constructions)

No limits for materials such as: Plastics, seals, rubber, Teflon, wood, wood composites, natural or synthetic stone, tiles, aluminium, copper, brass, bronze, stainless steel, titanium, steel

Total warehouse capacity for

base material up to 1500 ton

Extensive warehouse stock for:

- Sheet stainless steel (1.4301, 1.4541, 1.4571, 1.4404, etc.)

- Sheet stainless steel foils from 0.05 mm (1.4310, 1.4301, 1.4404)for shims and lining plates

- Sheet C-steel(S235JR, S355J2, P265GH, Hardox, etc.)

- Sheet aluminium (various alloy qualities)

- Sheet duplex (1.4462, 1.4162)

- Wearing plates

- Sheet copper

- Tube and rod steel in many qualities and dimensions on request

- Option for attesting and transfer of markings 3.1 and 3.2/EN10204

- Cut in connection with forming

- SK processing and surface treatment (sand or ceramic blasting) possible