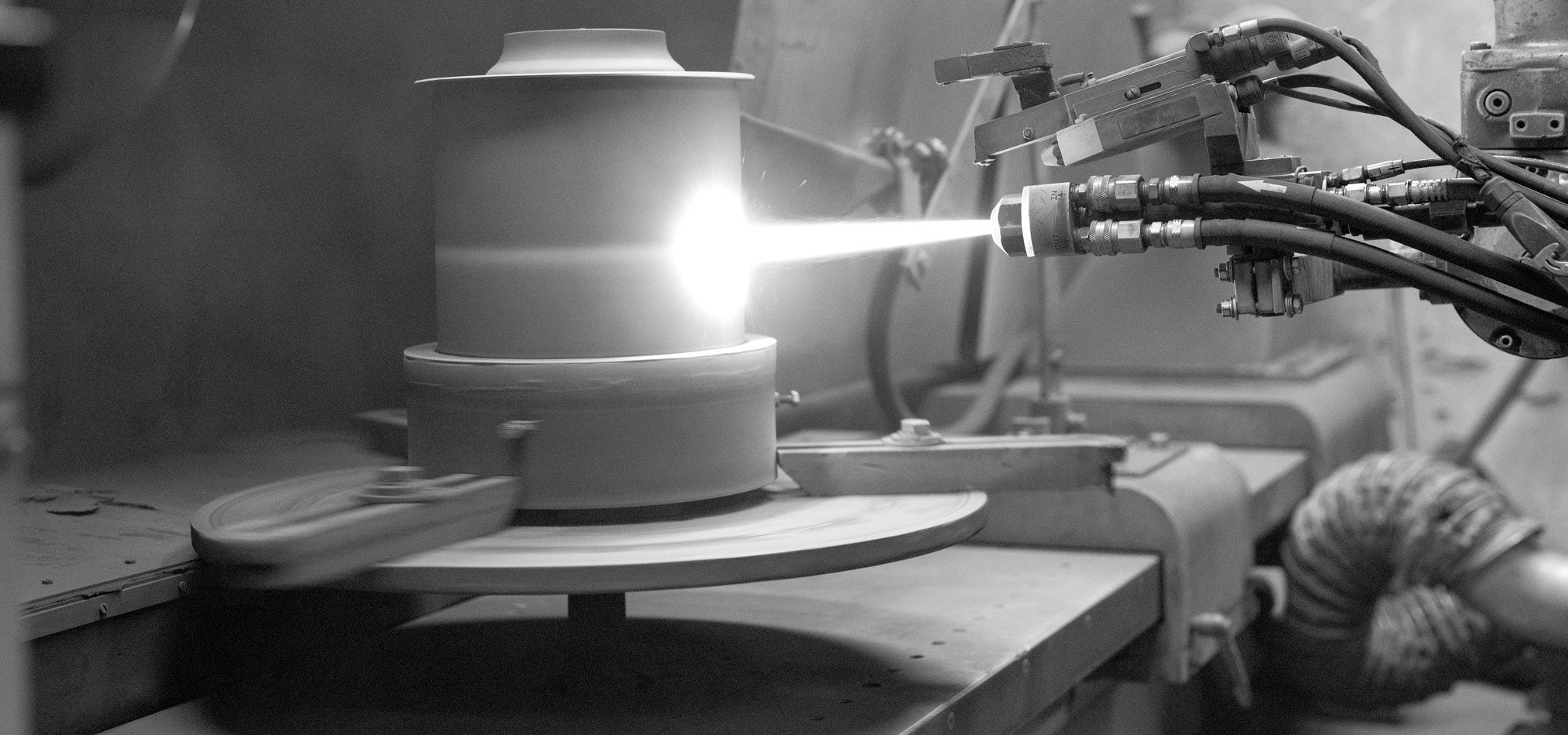

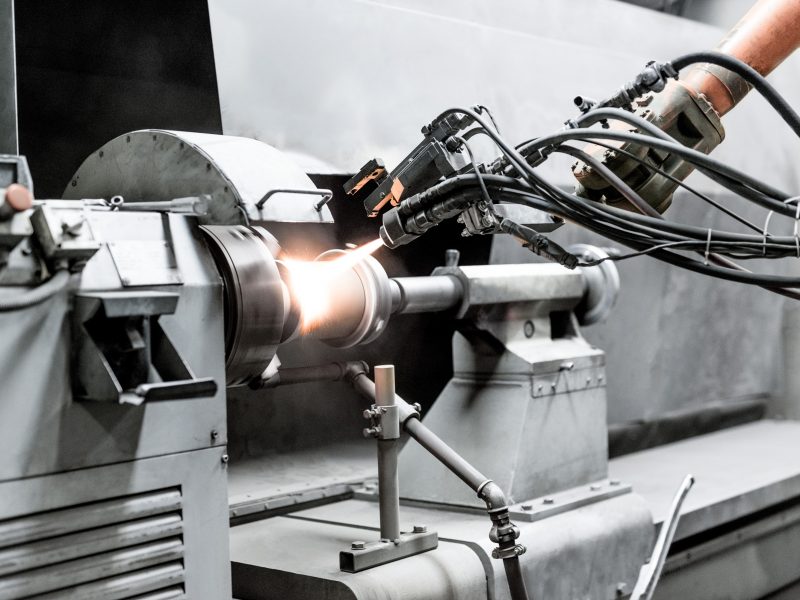

Thermal coating

Special surfaces

We have been providing thermal coating as our own sphere of competence since 2001. A 6-axis robot with a CNC turning appliance serves as the handling unit. The thermal coating is an innovative and cost-saving method to provide surfaces with special characteristics that result in increased performance. (e.g. wear and corrosion resistance, thermal and electrical insulation or conductivity, improved grip characteristics, and more)

Versatile and efficient potential applications:

The result is a great number of application opportunities, e.g. in pump construction, for paper and printing machine engineering and in petroleum production to name just a few.

The most important advantages of thermal coating are:

- Every metallic base material can be coated

- Many plastics can be coated

- Weight reduction through the use of lightweight metal

- Longer service life

- Cost savings

- No structural changes in the base material

Typical applications for new production and repair

- Clearance fit (shaft seal, stuffing boxes, friction bearing surfaces, cylinder and bearing surfaces …)

- Repair of bearing seats

- Fibre and wire-guided parts

- Thermal and electrical insulation > conductivity

- Grip layers

- Corrosion protection

- Abrasive wear

- Scrap restoration

- Armouring

Coating materials

The coatings are usually made of metals, ceramics, carbides or composite spraying materials to meet certain physical requirements.

Coating materials are, e.g.:

Non-rusting steels, zinc, tin, nickel, monel, Cermets, aluminium bronze, chromium steel, molybdenum, nickel-based alloys, ceramics (chromium oxide, aluminium oxide, titanium oxide), bronze, bio materials, carbides (tungsten carbide, chrome carbide), Hastelloy B, C

CONTACT US:

You can have us thermally coat your product. We even offer you complex components with coating and mechanical machining in tank construction and mechanical engineering.

DI (FH) Christian Horn

Division Management Mechanical Processing,

Thermal Coating, Complete Systems

Phone: 03173 – 2320 -10