Surface treatment

With the aid of the methods for surface technology we can paint, sand blast or ceramic blast which optimises components and machine elements to a defined requirement profile. To accomplish that, we provide you with the technical equipment and expertise with more than 35 years of experience in innovative surface treatment (e.g. for chemical plants, steel waterways engineering, industrial plants, etc.).

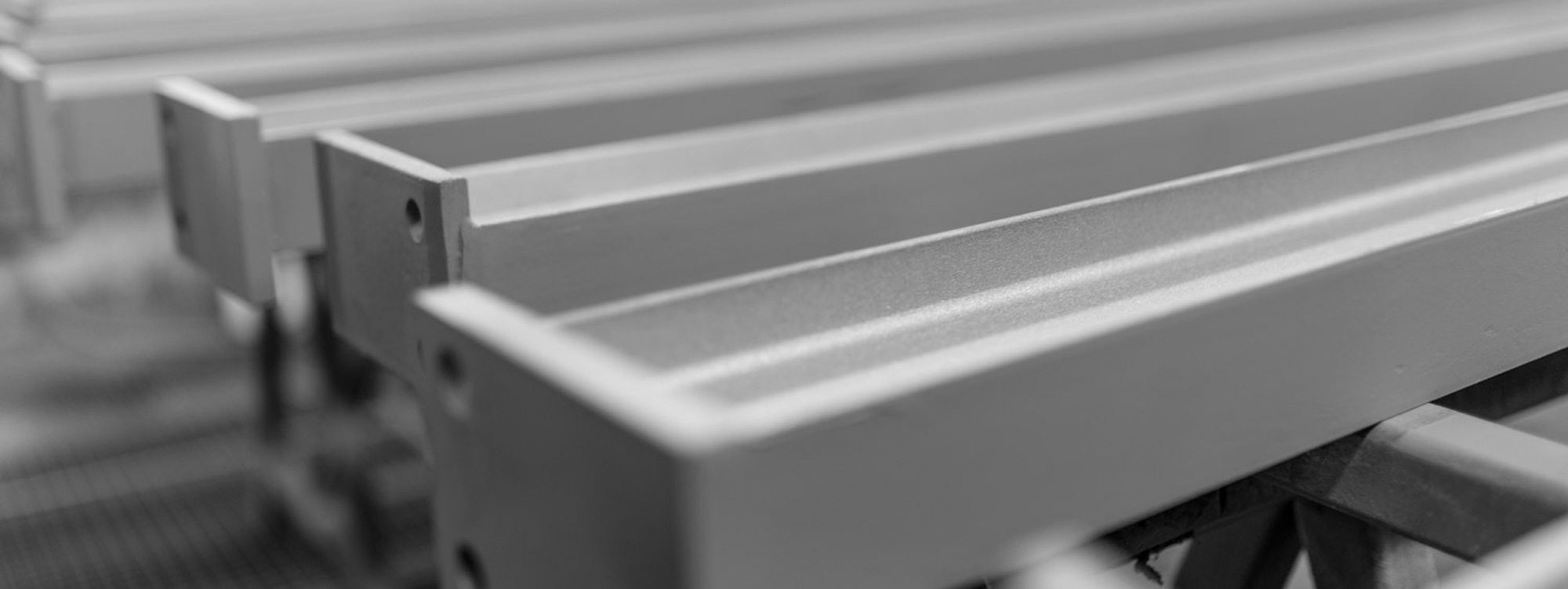

Painting

- Cabin size 9 x 6 x 6 m

- Small parts and assemblies up to large parts – max. crane capacity 2 x 10 t

- Spraying: Airless, air gun …

- Quality assurance: Layer thickness measurements, cross-cuts, etc. as per requirement

- Multiple coatings (base, intermediate and topcoat)

- Highly-varied coating materials based on the customer specifications

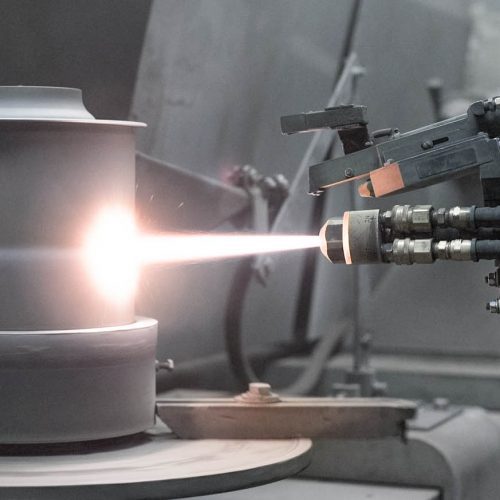

Ceramic blasting for stainless steel

- Cabin size 6 x 6 x 6 m

- Small parts and assemblies up to large parts to 16 t total weight

- Homogeneous silky surface approx. Ra 1.6

- Blasting of wood elements, furniture for rustic surfaces

- Similar to glass bead blasting – more beautiful surface – ideal alternative to pickling

CONTACT US:

We provide competence and manpower for processing standard steel and stainless steel in the area of tank construction and mechanical engineering, but we also have many years of expertise in the area of mechanical machining and thermal coating.

Edith Gutschelhofer

Division Management Tanks & Mechanical Engineering,

Blank Cut Forming, Skilled Worker Leasing

Phone: 03173 – 2320 -12